New Products

Productinfo

Product Description

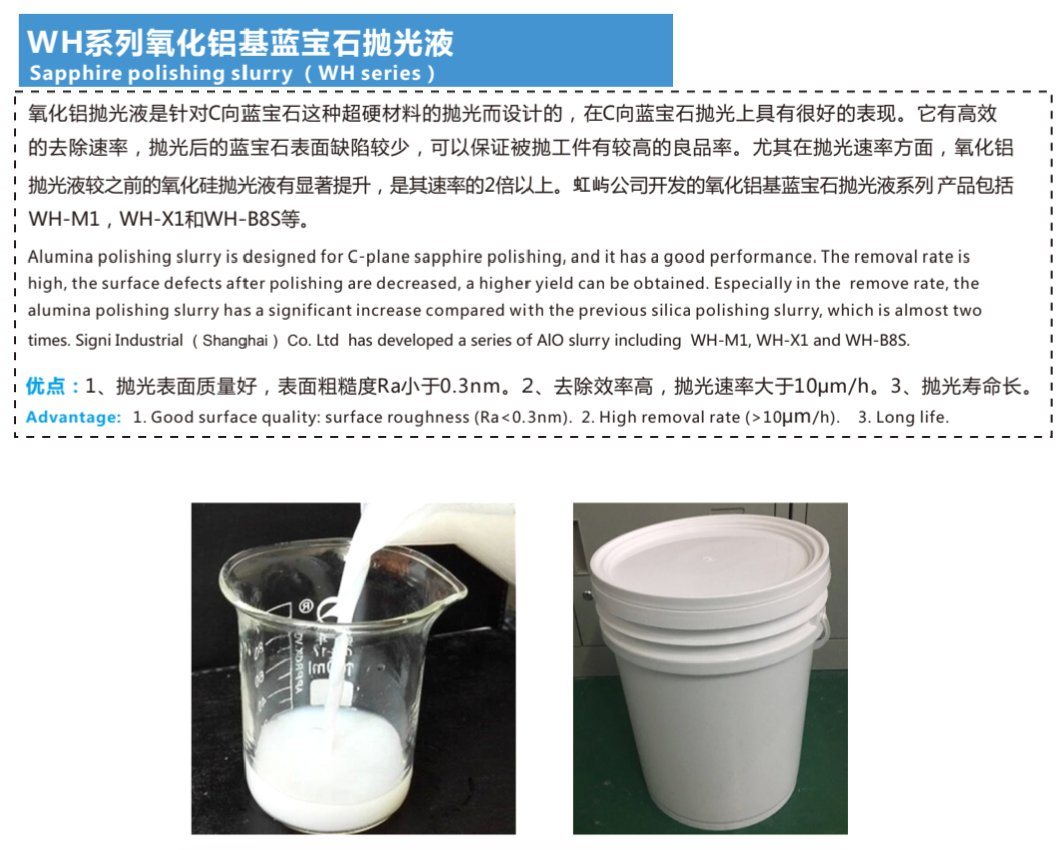

1. Appearance:White water base suspension

2. Application:

Polishing semiconductor wafers, precision ceramic, metal and other materials.

3. Specification:

Size (micron): 0.30,0.20,0.15,0.10

PH: 11-13 3.5-4.5

Content % :19-22 29-31

Suspensibility good good

4.Characteristics:

(1) High purity alumina particles dispersed in deionized water medium

(2) Higher hardness makes it have good grinding performances than silica polishing slurry, not only can achieve higher grinding effect, but also can get better surface roughness.

Packaging:

500 ml/bottle, 25 kg or 200 kg/barrel.

Customizations are available upon requests.

Storage:

Keep the stored temperature at 0~35℃ (32~95 °F). Frozen can result in irreversible product degradation below 0℃. High temperature above 35 ℃ may accelerate the

growth of micro-organisms and gelation, as well as decrease the long-term stability of the silica sol. Generally, the storage time of alkaline slurries is about two years and of acidic slurries is

about half a year.