New Products

Productinfo

Product Description

The high precision superabrasive cutting wheels are mainly used for precise cutting and slotting kinds of electronic

component and precise part in the electronic information and the mechanical fields.

Main features

1.High precision, for grooving and cutting with less procedure

2.Narrow cutting kerfs, for saving valuable material

3.Sharp-edged, high efficiency

4.Good rigidity, high strength and long life span

Cutting wheels without steel plate

The cutting wheels without steel plate are manufactured with identical material. Thin thickness and high

precision, they are mainly used for grooving and cutting with high accuracy and slight cutting depth.

There are two kinds of bond: metal bond (M) and resin bond (B).

Metal bond cutting wheels without steel plate

1.The grits are strongly held by the metal bond, 2.The wheels have good wear resistance, good shape

maintenance and long life span.

Resin bond cutting wheels without steel plate

The resin bond cutting wheels can self-sharpen and cut sharply. The quality of surface can be improved due

to the elastic resin bond.

Spec and dimension of the high precision cutting wheels without steel plate

The models of cutting wheels without steel plate divide into 1A8/1 type without water slot and 1A8/2 type

with water slot.

Model specification and the precision for reference(mm)

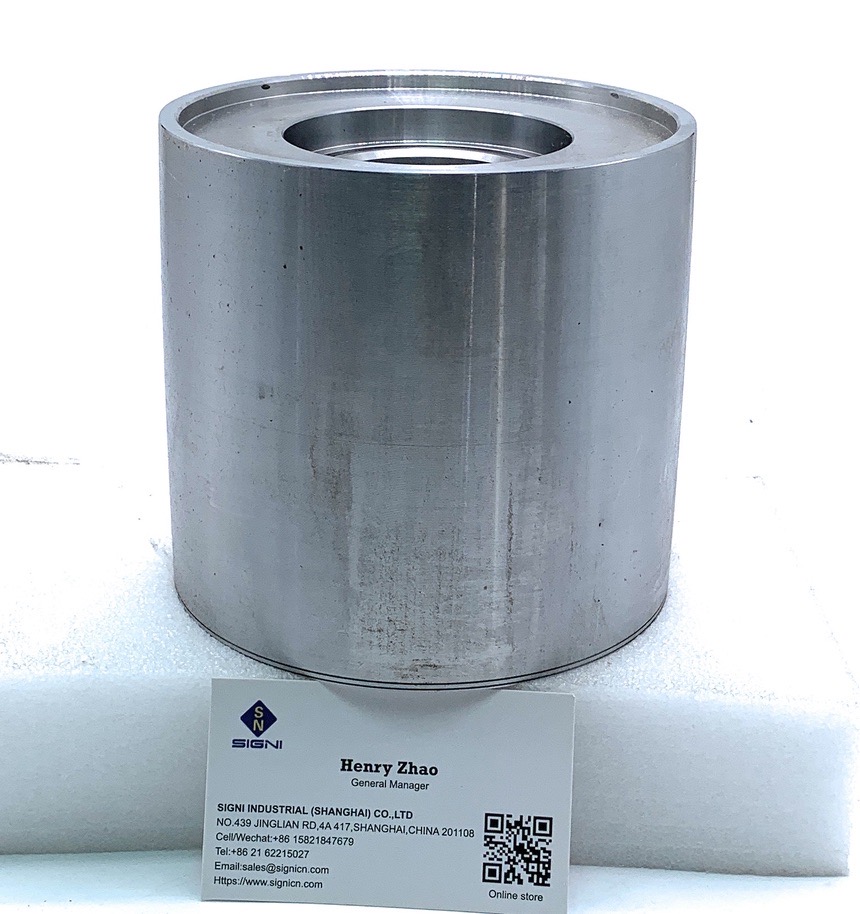

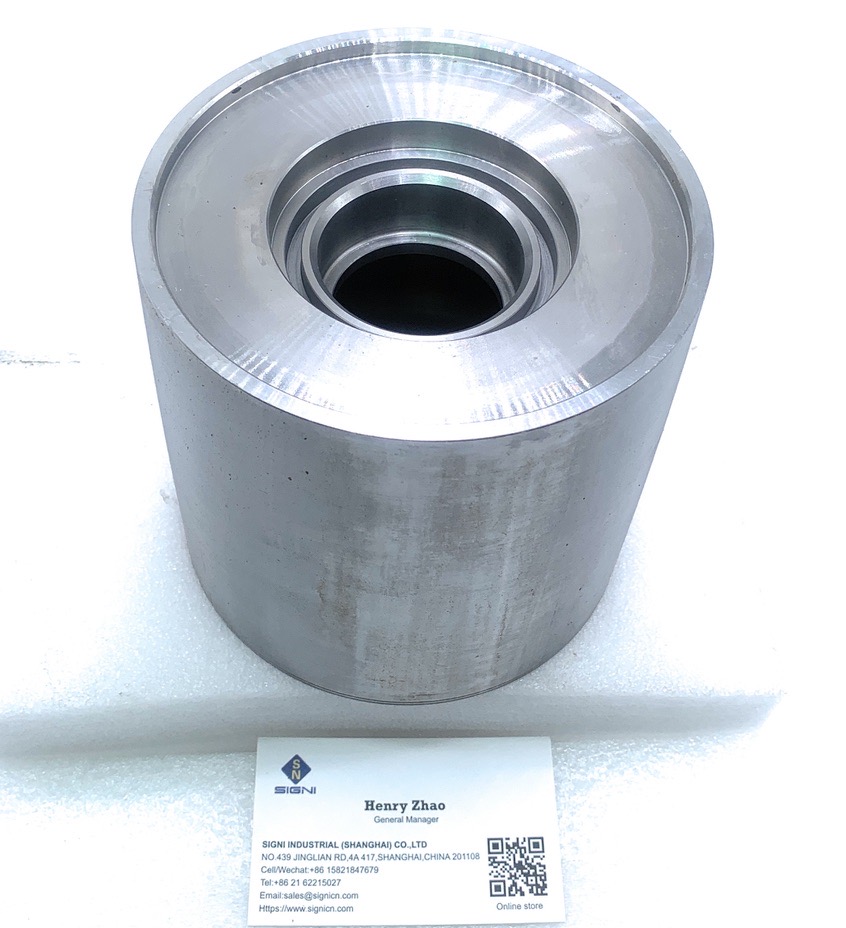

High precision cutting wheels with steel core

This kind of cutting wheel is compound of steel plate and work layer. The steel plate has high strength and

high rigidity. They are generally used for deep cutting and grooving.

The cutting wheel bond divides into three kinds: the metal bond (M) ,resin bond (B) and mixture of metal

and resin(M/B).

Metal bond cutting wheels: The grits are strongly held on; the wheels have good wear resistance, long life span and good shape maintenance. Resin bond cutting wheels: These wheels can self-sharpen and cut sharply. The work quality can be improved due to the elastic resin bond. The spec and dimension of the high precision cutting wheels with steel plate The models of cutting wheels with steel plate divide into 1A1/3、1A1R/4 type without water slot and 1A1/5、 1A1R/6 type with water slot. Cutting wheels of 1A1 type: The thickness of work layer is as same as steel plate. They are mainly used for precise grooving and cutting. Cutting wheels of 1A1R type The thickness of work layer is higher than the steel plate. They have advantages for removing chips and cooling. They are mainly used for deep cutting and grooving of component. Model specification for reference and the precision(mm) High precision special type cutting wheels According to customer’s requirement, our institute also can provide with special type cutting wheels (such as 3A1, 14A1, 1B1, 1F1, 1E1, 1GN1 and etc.) Order guideline: When first order, please provide the following parameters so as to select the most suitable cutting wheels. 1. Types: 1A8、1A1、1A1R、3A1、14A1、1B1 and so on 2. Specification:Abrasive, grit, bond type, outer diameter, thickness, inner diameter, work layer width, steel plate thickness and so on. 3. Usage: The work piece, cutting size, cutting material, grooving or cutting off and so on. 4. The application conditions: The machine, the rotational speed, feed speed, cutting depth; dry or wet cutting and so on. 5. Cutting requirement: Cutting precision, rip request, superficial integrity and so on. 6. Special requirement: for example: Whether combination use, whether the resin bond cutting wheel needs the electric conduction, whether there are water slots on the periphery of cutting wheel, number and specification of the water slots, whether 1A1 type cutting wheel with steel plate has slots for removing chips on the outer profile and so on. Attention: 1. Before installing cutting wheels, please carefully inspect and confirm the cutting wheel has no distortion, crack, rip and so on. 2. When the cutting wheel has a sign of rotation, it must be consistent with rotation direction of the machine. Otherwise it cannot cut sharply and it is difficult to bring the performance of the cutting wheel into play. 3. Please do not use the cutting wheels that do not conform to requirement. 4. If abnormity appears in the process, it should be immediately stopped. 5. When cutting wheel is not sharp, you must dress the cutting wheel. Otherwise, it will lead to overheat and excess load which will cause the cutting wheel to damage. 6. When rotating, it is strictly prohibited to control with hand and touch the cutting wheels with body 7. The cutting wheels are only used for grooving and cutting off. Otherwise it is easy to occur abnormity because of uneven stress.