New Products

Productinfo

Product Description

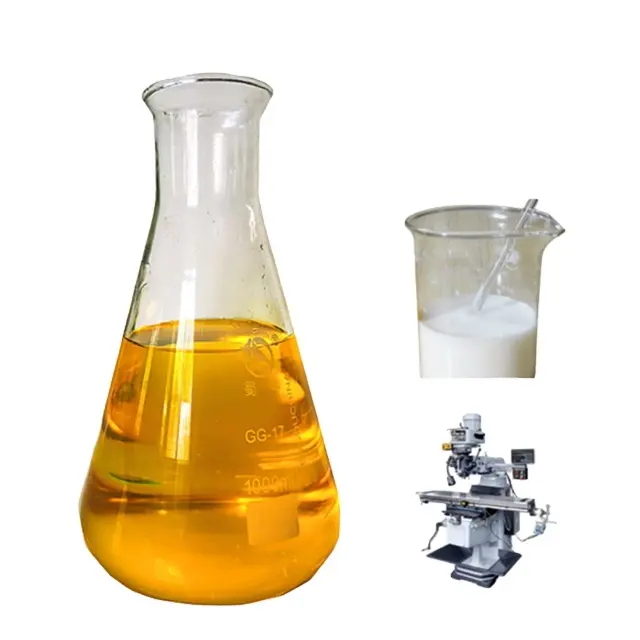

Other Polishing Slurry

AO series and SC series polishing slurry are produced from superior fine abrasives. They’re suit for the super finishing of high-precision optical materials, hard disk substrates, fiber optic connectors, magnetic head, crystal compounds, ceramics, IC manufacturing etc. with good dispersibility, uniform particle size distribution, and high removal rate performance .

Specifications:

|

Series

|

Type

|

Particle Size (D50,μm)

|

Density(wt℅)

|

Applications

|

|

CO

Series

|

CO-1/4D

|

0.2-0.3

|

10-60

|

Fine Polishing

|

|

CO-1/2D

|

0.4-0.6

|

10-60

|

Surface polishing process of MTRJ fiber optic connectors , optical glasses and lens etc.

|

|

|

CO-1D

|

0.8-1.2

|

10-60

|

||

|

AO

Series

|

AO-1/2D

|

0.4-0.6

|

10-60

|

Surface superior finishing of fiber optical connectors, hard disk, ceramics, alloys, crystal compounds, optical glasses etc.

|

|

AO-2D

|

1.6-2.4

|

10-60

|

||

|

AO-3D

|

2.6-3.6

|

10-60

|

||

|

SC

Series

|

SC-1D

|

0.8-1.2

|

10-60

|

Surface superior finishing of fiber optical connectors, hard disk, ceramics, alloys, crystal compounds, optical glasses etc.

|

|

SC-3D

|

2.6-3.6

|

10-60

|

Note: Customizations are available upon the requests.

|

|

1) Use personal protective equipments although it is non-dangerous slurry and follow MSDS preventive safety practices

2) Mild agitation keep the slurry suspended before using

3) Adjust to suitable concentration upon the using conditions

Packaging :

50ml/bottle, 250ml/bottle and 500ml/bottle

50ml/bottle, 250ml/bottle and 500ml/bottle

Storage:

Maintain storage at temperature 0-35℃

Maintain storage at temperature 0-35℃

Period of validity:

One year