New Products

Productinfo

Product Description

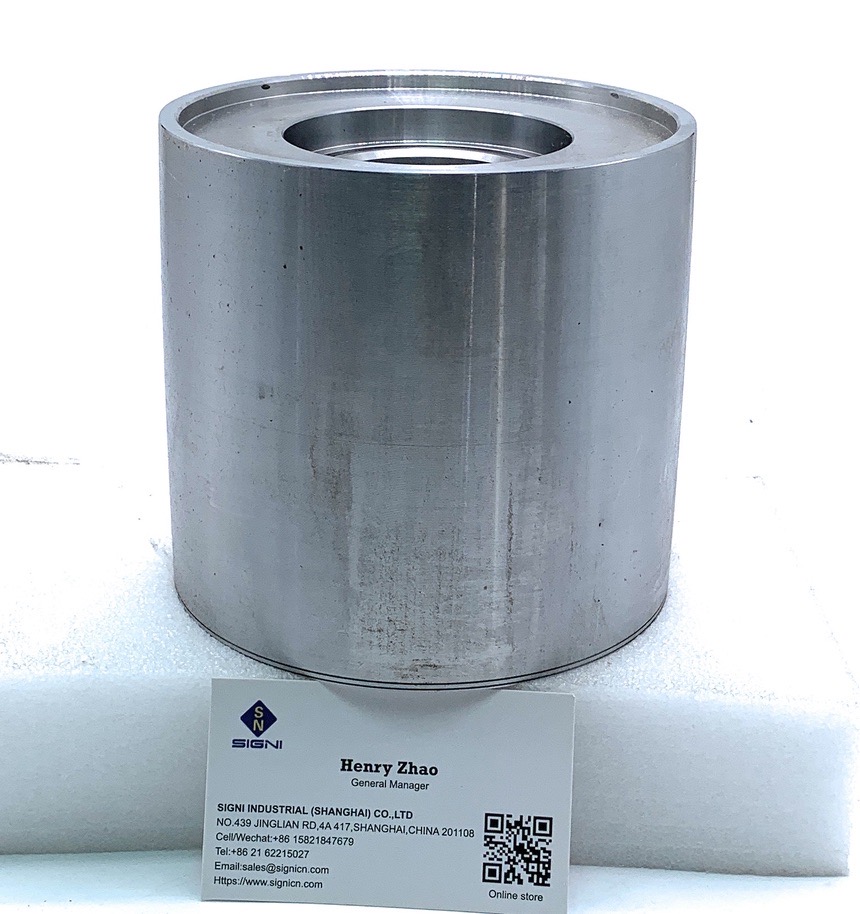

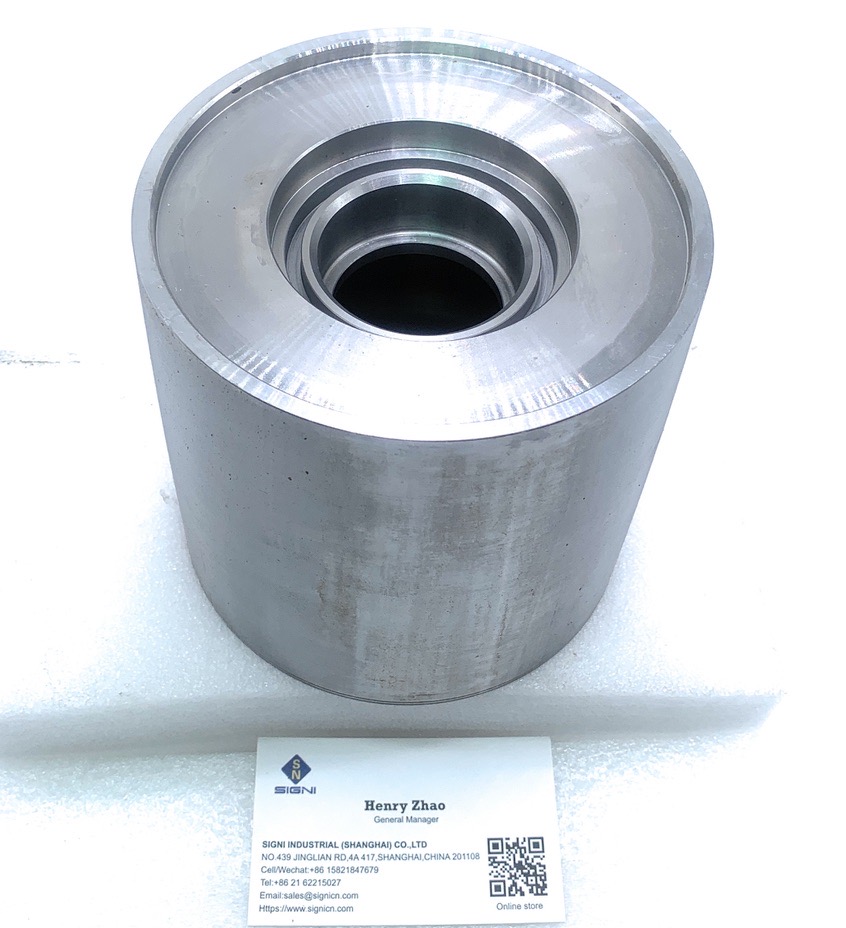

SIGNI RAIL GRINDING WHEELS FOR LORAM GRINDERS

250mm x 76.2mm x 152.4mm hole Plate Mounted with 3 location spigots 3/8”UNC fibre-glass wrapped on periphery.

SIGNI RAIL GRINDING WHEELS FOR HARSCO GRINDERS

155mm x 80mm x 5/8” UNC claw back plate, fibre-glass wrapped on periphery. 280mm x 30mm x 25.4mm hole. Aluminium backing plate.

260mm x 76.2 or 82.5 or 88.9mm thk x 152.4mm aluminium backing plate.

SIGNI RAIL GRINDING WHEELS FOR SPENO GRINDERS

250mm x 75mm x 150mm, fibre-glass wrapped on periphery.

260mm x 30mm x 200mm aluminium backing plate

180mm x 105mm x 90mm, fibre-glass wrapped on periphery.

SIGNI RAIL CUTTING WHEELS

356mm x 4mm x 25.4mm hole

Aluminium Oxide Grit: A24SBF Speed rated 100m/s

Zirconia Grit: 3ZA24PB Speed rated 100m/s

Lasts longer, more cuts per wheel than aluminium oxide cutting wheel.

SIGNI RAIL GRINDING WHEELS FOR GEISMAR GRINDERS

Frog-Grinding machine:

Grinding Wheel size: 254mm x 40mm x 76.2mm hole,

recessed both sides 170mm x 10mm.

MP12 Grinding Wheel size:

150mm x 65mm/80mm x 80mm hole with 6 x M8 nuts on 115mm PCD

150mm x 72mm x 55mm hole with 4 x M8 nuts on 90mm PCD

MV3 Grinding Wheel size:

150mm x 80mm hole safety back plate with 5/8”UNC nut, recess 80mm x 58mm

T35 mounted on Safety Back Plate:

Grinding Wheel size:

150mm x 55mm x M20 thread nut

150mm x 80mm x 5/8”UNC thread nut

Flap Disc - Grinding the top of the Frog

Glass fibre backed zirconium grit 180mm dia x 22mm hole, 60 & 80 Grit

SIGNI RAIL GRINDING WHEELS FOR Robel Grinder: •

125mm x 65mm x M20 thread nut to fit Robel machine type 13.47

• 260mmx 25mm x 120mm hole to fit Robel machine type 13.61

SIGNI RAIL GRINDING WHEELS FOR Autech Grinder:

100mm x 110mm x M20 thread nut

SIGNI RAIL GRINDING WHEELS FOR Portable Machine •

Taper cup wheel type 11 ,Various sizes with either threaded nut insert or plain hole

1,high-pressure grinding wheel for steel plant

The products are used for operations ranging from defects-removing grinding of steel blooms / slabs, ingots and sheets all the way to partial / full oxidized

surface grinding and conditioning of products in steel industry. Their features of heavy duties,

high removal ratios, and high cutting efficiencies lead to less operator intensities, better environmental

conditions, and improved after-ground surface qualities of the workpieces.

Grains:A,ZA,SA,SO

Grain Sizes:8#—36#

Max Operation Linear velocity:80 M/S

Max Operation Load:10000N

Specifications:Φ500×65×203,Φ500×100×203

Φ610×75×203,Φ610×75×305

Φ735×100×305,Φ735×125×305,

2,Heavy Duty Steel Bloom / Slab Hot Conditioning Wheels

The products are adopted in online grinding of blooms / slabs during hot rolling at relatively high

working temperatures. The wheels are specifically developed for state-of-the-

art technology of hot grindings of steel blooms / slabs. Compared with cold grinding wheels this

technology takes advantage of thermal energy of workpieces, leads to higher productivities, gets

rid of surface cracking on workpieces, and obtains improved surface polish.

Working Temperature:800-1000°C

Grains:ZA,SO,SG

Grain Sizes:8#—36#

Max Operation Linear Velocity:80 M/S

Max Operation Load:20000N

Specifications:Φ735×100×305,Φ735×125×305,

Φ915×100×305,Φ915×125×305

3,Roller Fine Machining Wheels

We developed this product especially for machinery roller manufacturers and metallurgical

industries, to be used for rough and fine grindings of ferro-

chrome rollers, rollers with high nickel and chrome alloy contents, thermal-

stability alloy rollers, high chrome steel rollers etc.

Grains:GC,WA,SG,SC,PA,ZA

Grain Sizes:24#—240#

Max Operation Linear Velocities:Fine Grinding45 M/S,

Rough Grinding60M/S

Max Operation Load of Rough Grinding:2000N

Specifications:Φ610×75×305,Φ750×75×305,

Φ900×100×305,Φ1066×150×305

4,Raw Grinding Wheels and Flat Wheels

These products are designed for surface conditioning of steel ingots, steel blooms / slabs, and

other cast parts in steel, casting, and machinery industries. They can be used to debur and list

edge removing of castings, and can be used to conditioning of hard-to-be-

ground materials such as titanium, titanium alloy, high manganese steel, stainless steel too.

Bonding Agent:B

Sizes:D≤1100MM H≤200MM,and wheels of various hardness

Grains :A,WA,C,GC,

Grits:16#—120#

Max Operation Linear Velocity:40 M/S

Specifications:Φ400×50×127,Φ400×50×75,Φ400×50×203

Φ400×40×127,Φ350×40×127,Φ350×40×75

Φ400×50×75,Φ400×40×203,Φ500×65×203

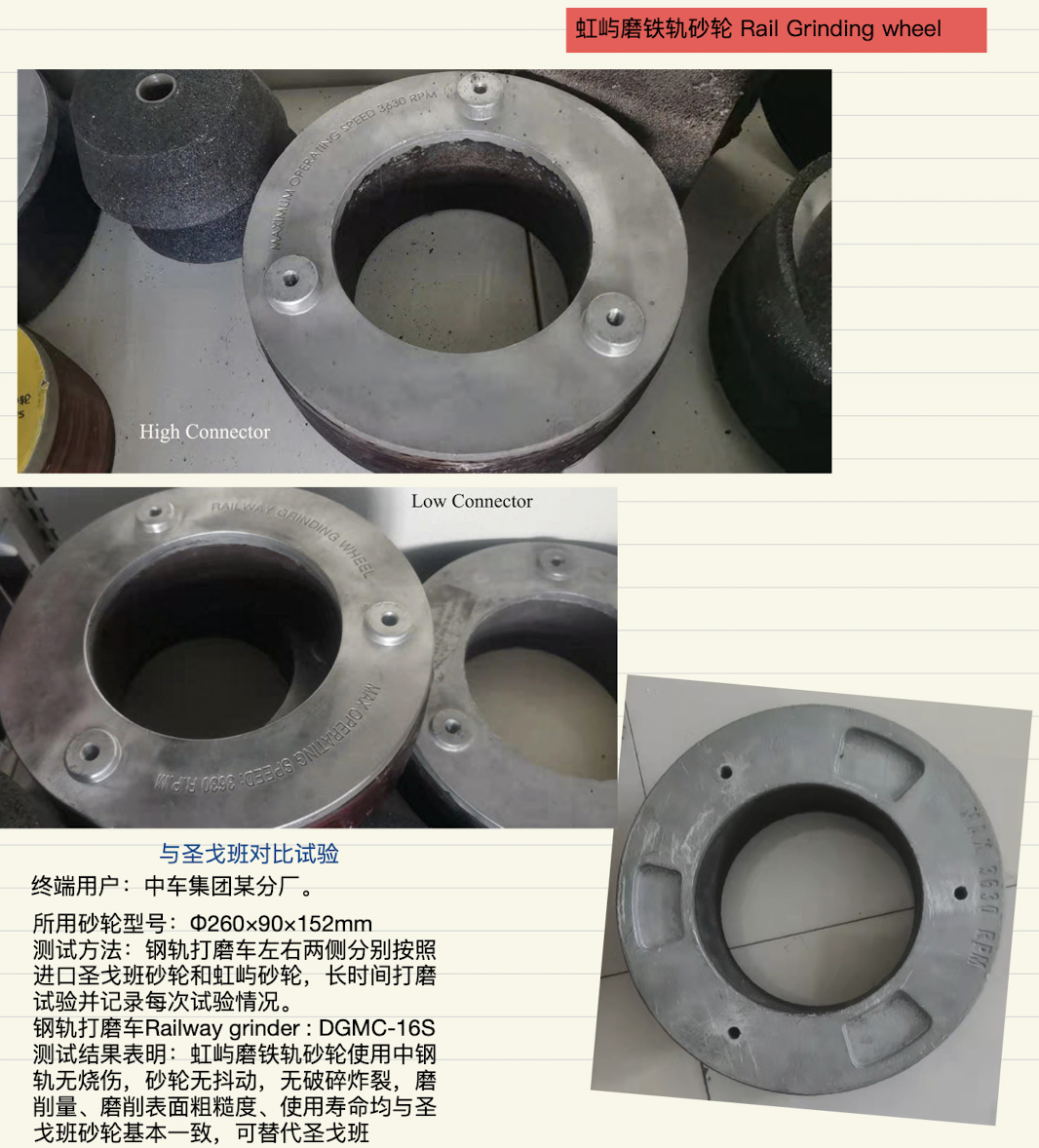

5,Heavy Duty Rail Conditioning Wheels

This is the abrasive specifically for surface grinding of steel rails. The products are accessories to

heavy steel rail grinding machines imported from overseas. They are superior of heavy duty

grinding, high cutting efficiency, and long product life.

Grains: ZA.SA

Grain Sizes: 16#-24#

Max Operation Linear Velocity: 70M/S

Max Operation Load: 5000N

Specifications: Φ260×85×152mm. Φ250×75×150mm.

6,Sectional Wheels of Resin Bonding

The products are preferred to plane conditioning of metal and nonmetal material in machineries,

with high grinding efficiency, high quality after-ground surface polish.

Bonding Agent: B

Grains: A .WA. C. GC.

Grain Sizes: 24#-120#

Product Codes: WP.WT

Specifications: WP150*80*25. WT150*100/85*35.

7,Fiber Backing Resin Cutting Wheels for Special Utilities

The products are applied to cutting of hard-to-be-

machined metal materials such as steel rails, high speed steel, stainless steel, manganese steel etc.

They are unsubstitutable cutting tools in railways, machineries, and steel industries.

Specifications:Φ500×3.2×32 .Φ400×3.2×32

Grains: ZA .SA

Grain Sizes: 24#-36#

Max Operation Linear Velocity: 80~100 M/S

Tel/Whatsapp: +86 15821847679

Email: sales@signicn.com