New Products

Productinfo

Product Description

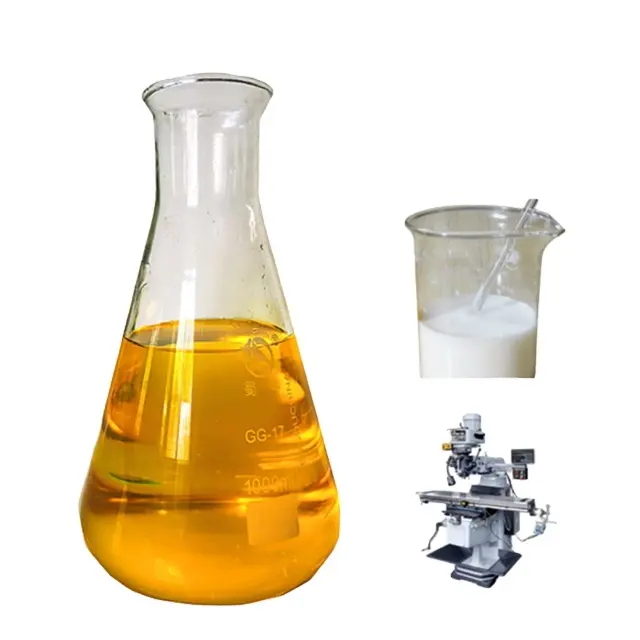

SIGNI Chemical Mechanical Polishing (CMP) Slurries are colloidal silica liquid made of high purity deionized water, highly

engineered chemical additives and abrasives that chemically and mechanically interact with work piece surface to remove

excess materials, therefore smooth or flatten the surface. They are widely used for nanometer scale chemical mechanical

polishing fields such as silicon wafers, compound crystals, optical apparatus, and sapphire polishing. The slurries have a

wide range of diameter from 10 to 150 nm to meet different requirements. There are alkaline and acidic slurries based on

the pH.

SIGNI CMP slurries are developed under the concepts of high purity, high removal rate, high dispersion and scratch-free performance. Signi supplies CMP polishing slurry to customers around the world and is the most competitive in quality

and price.

Features

High speed polish: with large particle of colloidal silica (Grit size up to 150 nm)

Controllable size: a wide range of custom-graded colloidal silica slurries from 10 to 150 nm that suits individual needs and applications

High purity: the content of Cu2+<50 ppb, without contamination on the work piece

Super-smooth polishing: with the particle of SiO2, avoid scratch on the object surface

|

Typical Properties |

||||||

|

Alkaline Type pH: 9.8±0.5 |

SOQ-2 |

SOQ-4 |

SOQ-6 |

SOQ-8 |

SOQ-10 |

SOQ-12 |

|

Acidic Type pH: 2.8±0.5 |

ASOQ-2 |

ASOQ-4 |

ASOQ-6 |

ASOQ-8 |

ASOQ-10 |

ASOQ-12 |

|

Grit Size(nm) |

10~30 |

30~50 |

50~70 |

70~90 |

90~110 |

110~130 |

|

Appearance |

Milk white or semitransparent liquid |

|||||

|

Density (g/ml) |

1. 15±0.05 |

|||||

|

Component |

Content(wt%) |

|

SiO2 |

15~30 |

|

Na2O |

≤0.3 |

|

Heavy metal impurity |

≤50 ppb |

|

Silica Wafer Polishing Reference Data |

|

|

Polishing Pressure |

150 ~ 250 g/cm2 |

|

Polishing Temperature |

32 ~ 40 °C (89 ~ 104 °F) |

|

Dilution |

1:1 - 20 |

|

Polishing duration |

3 ~ 6 minutes |

Packaging:

500 ml/bottle, 25 kg or 200 kg/barrel.

Customizations are available upon requests.

Storage:

Keep the stored temperature at 0~35℃ (32~95 °F). Frozen can result in irreversible product degradation below 0℃. High temperature above 35 ℃ may accelerate the

growth of micro-organisms and gelation, as well as decrease the long-term stability of the silica sol. Generally, the storage time of alkaline slurries is about two years and of acidic slurries is

about half a year.